Vendor Managed Inventory, also known as VMI, is an effective strategy for companies to better manage their supply chain needs. In this article, we will take a closer look at how VMI can help streamline your inventory management processes while also reducing overall administrative costs. Ready? Let’s dive right in!

What is vendor managed inventory?

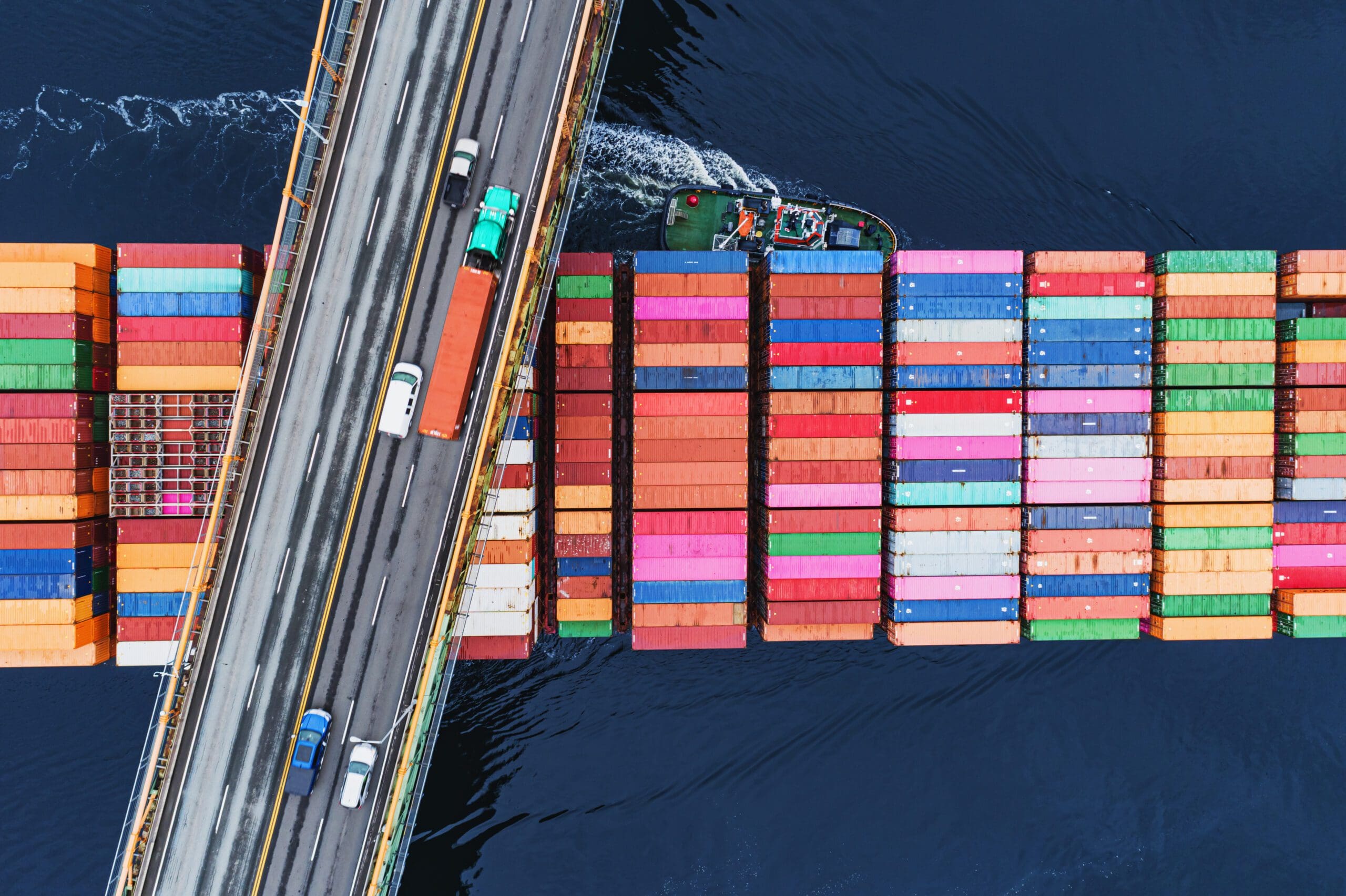

Vendor managed inventory refers to a supply chain strategy in which a supplier of goods assumes responsibility for the management, supervision, and optimization of a business’s inventory. In a typical VMI arrangement, vendors handle every aspect of a business’s inventory to ensure that they maintain enough stock to satisfy customer demand. Put simply, vendor managed inventories are owned by the vendor but are located and sold at a business’s premises.

To help you better understand the concept of vendor managed inventory, check out this example:

Let’s say a hypothetical superstore named KickMart has an existing VMI relationship with Hisense USA. In this case, the vendor is Hisense USA and the client is KickMart. Hisense USA supplies KickMart with various types of home appliances and makes sure that KickMart maintains optimum stock levels.

For a VMI partnership to be successful, both parties need to establish data-sharing practices to make sure that replenishment calculations are relevant and accurate. The ultimate goal of VMI is to create a seamless process that determines the appropriate re-order quantity based on current demand and agreed-upon stocking levels.

How does vendor managed inventory work?

- Set expectations. Much like most business relationships, both the vendor and the customer need to agree on specific goals that would define the success of their VMI partnership. This would provide the necessary foundation and structure to the partnership and determine clear roles and responsibilities for each party.

- Maintain constant communication. For a VMI relationship to work, a close strategic relationship needs to exist between both parties to make sure that necessary information is accessible. Sustained communication fosters increased transparency and mitigates the risk of stockouts or overstocking.

- Continuous improvement. To optimize important inventory management processes, a VMI partnership should also enable the vendor and the client to freely discuss rooms for improvement. Identifying gaps in your supply chain process allows you to quickly react to market changes and address possible areas of concern.

What is the main difference between vendor managed inventory and traditional inventory management?

The main difference between VMI and traditional inventory management is the way inventory is handled. When it comes to traditional inventory management, a business handles every aspect of the inventory management process from sales forecasting to order fulfillment. On the other hand, a vendor managed inventory shifts the responsibility of inventory management and logistics entirely to the vendor. Customers that partner with a vendor managed inventory services provider enjoy multiple benefits from lower costs to more efficient forecasting capabilities.

Is vendor managed inventory right for you?

If you are a rapidly growing business that manages complex inventory levels and seasonally experience spikes in demand, then a vendor managed inventory strategy may be right for you. A VMI provider can help you streamline your auditing processes to make sure that you are holding just the right amount of inventory at any given time. Some of the biggest retailers that use VMI are Walmart, Bosch, Home Depot, and Amazon.

What are the benefits of vendor managed inventory?

Optimal Stock Levels – When done correctly, vendor managed inventory enables businesses to optimize their stock levels by aligning inventory replenishment practices with existing and potential customer demand. By establishing a seamless inventory management system with a VMI partner, businesses can mitigate the risks surrounding stock levels and only carry the right amount of products.

Improved Forecasting Ability – Another benefit of partnering with a VMI provider is improved demand forecasting for all products. Through the exchange of important sales and demand forecasting data, you and your VMI partner can anticipate trends, sales patterns, and future demand more effectively.

Lower Costs – From lower carrying costs to more efficient inventory management costs, having a VMI partner allows businesses to reduce various supply chain expenses. The vendor managed inventory model also saves businesses money by placing bulk orders which usually secures better discounts.

Improved Data Insights – Along with improving your forecasting ability, partnering with a VMI provider means better data and technology sharing between both parties. This translates into improved data insights which, in return, fosters continuous improvement.

Are there risks involved in the vendor managed inventory process?

Unreliable Supplier – Like most business partnerships, an unreliable partner could spell disaster for your operations. This may sound harsh but you’d be surprised at the number of unreliable suppliers out there. While it takes time to build a trusting relationship, there are some questions you could ask your potential vendor to make sure that you are choosing the right partner:

- Have you ever partnered with similar businesses?

- What are your technological capabilities? Will it integrate seamlessly with our processes?

- Will you be able to come up with a strategic inventory management plan?

- What type of communication channels do you prefer?

- Will you be able to personalize and scale our processes in case we grow and expand?

Data Exposure – One significant disadvantage, when working with a third-party provider, is an increased vulnerability from data exposure. And when it comes to working with a VMI, it’s no different. As mentioned above, a VMI partnership only works when both parties establish data-sharing processes that would shed light on gaps in the supply chain processes. However, it also poses security concerns wherein data may be shared with other parties without the business’s consent. While definitely rare, it’s still something to keep in mind before partnering with a vendor managed inventory provider.

Slow Market Response – Changes in customer preferences and the overall market are, at times, impossible to predict. When the market experiences sudden changes, it could be difficult to secure the inventory you need especially if your VMI partner cannot meet your requests due to other contractual obligations.

Are vendor managed inventory and consignment stock the same?

While both concepts sound similar, vendor managed inventory and consignment are two different business principles. The biggest difference between the two is that consignment is a business arrangement that enables a consignee to sell a consignor’s goods. The consignor maintains ownership of the products and is paid by the consignee when inventory is sold. On the other hand, vendor managed inventory is a strategy that shifts the inventory management responsibility from the business to the vendor.

Are there alternatives to VMI?

By now, you may have an idea about what vendor managed inventory really is and the benefits that it can bring to your company. However, if you think a VMI partnership is not right for your business, there are other ways to properly secure and manage your inventory depending on your needs. Take consignment inventory for example. Consignment inventory is a cost-effective way for businesses to maintain stock levels at their stores without the need to pay for the products upfront. It’s a great way to keep your business running while ensuring a predictable cash flow.

If you’re looking for an alternative to vendor inventory financing, check out Kickfurther. Kickfurther is a unique type of inventory consignment platform that helps businesses fund their inventory needs through the help of supporters and fans. Inventory is often offered as a consignment opportunity or Co-Op wherein individual backers can participate in crowdfunding campaigns and, when inventory is sold, businesses pay their investors instead of the bank.

Wrapping Up

As a business, it’s important to regard vendor managed inventory partnerships as a highly collaborative business relationship. When choosing a VMI partner, make sure that they have the necessary industry know-how and the technological capability to be able to cater to your business’s unique needs. In addition, find a vendor that will help you tackle supply chain challenges as well as present opportunities that will help your business thrive and succeed.